What's Foam Used For?

How is Foam Used in Protective Cases?

Foam in protective cases is used in both the lid and the base to cushion and secure items, absorbing shocks and preventing movement during transport for maximum protection.

Benefits of Foam in Protective Cases

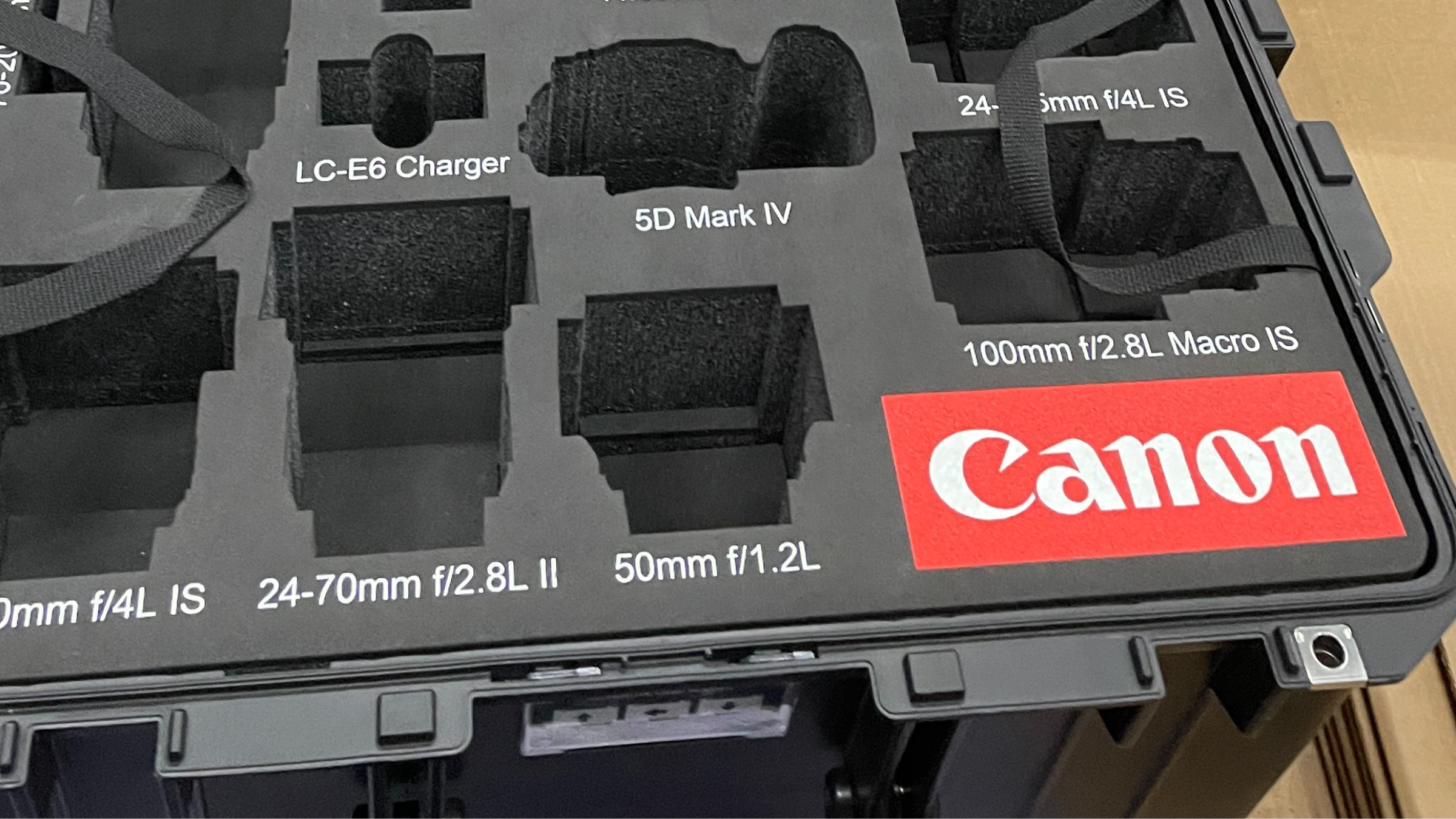

Custom Fit

Protection

Organization

Why Foam Works So Well

Foam is ideal for protective cases because it combines durability with cushioning.

It’s lightweight yet effective at absorbing impacts, making it perfect for protecting everything from electronics to delicate instruments.

Plus, with our MyCaseBuilder app, you can design foam that meets your exact needs.

Foam Glossary

Anti-Static Foam

Foam that provides maximum protection from static electricity for electronics like motherboards. Available in Pink. If storing laptops, cell phones, or other electronic devices, Anti-Static foam is not needed.

Go to Foam Types to learn more.

Base Foam

The foam insert that fits the bottom part of the case, not including the lid.

Base Depth

The usable, designable space in the base of a case.

Watch our Multiple Depths in One Cutout video to learn more.

Base Filler Pad

A foam pad (or pads) added to the base of a case to fill it to level for an accompanying insert. This is usually associated with cases employing a center channel for a telescoping handle. The height of the BASE FILLER PAD is usually NOT included in a case's BASE DEPTH dimension.

Cavities

Hollowed-out spaces, or cut-outs, within foam used to accommodate and secure items. These can be custom-shaped to fit specific objects. You can add unlimited cut-outs to your designs.

Case Depth

The total usable, designable space in a case equal to the BASE DEPTH plus LID DEPTH.

Watch our Depth Warning Explained video to learn more.

Cell

The individual air-filled pockets within foam material. The structure of these cells affects the foam's properties like density and flexibility.

- Open-Cell Foam: Foam with interconnected cells, allowing air and moisture to pass through. It is softer and more flexible, offering good cushioning but less moisture resistance (e.g., Ester).

- Closed-Cell Foam: Foam with cells that are not interconnected, providing better insulation and moisture resistance. It is firmer and more resilient (e.g., ProCell, TopGuard).

Channel

A cavity running perpendicular to an array of slots that serves as an elongated finger notch.

Chamfering

A chamfer is an angled cut, typically applied to base foam, to ensure a precise fit in cases with a "draft" or taper—where the bottom and top dimensions of the case base slightly differ. This angled edge allows the foam to conform snugly to the case's interior shape.

Convoluted (Egg Crate) Foam

Egg crate foam features a wavy, contoured surface pattern resembling an egg carton. This design offers flexible cushioning and is commonly used as lid foam. It gently compresses against items in the base foam, helping to secure them and prevent movement.

Compression

The process of applying pressure to foam to compress it, affecting its density and firmness. Compression is a key factor in determining how well the foam will absorb impacts and return to its original shape.

Cross-linking / Cross-linked Foam (XLPE)

A process where the foam’s polymer chains are chemically bonded to each other, improving its strength, durability, and resistance to heat and chemicals. XLPE stands for Cross-Linked Polyethylene Foam.

Corner Radius

The measurement of the curvature of the corner of a case or a cavity.

Density

The mass of the foam per unit volume, typically measured in pounds per cubic foot (lb/ft³) or kilograms per cubic meter (kg/m³). Higher density foam provides more support and durability.

Durability

The ability of foam to withstand wear, pressure, and damage over time. Durable foam maintains its performance and appearance even with frequent use.

EVA (Ethylene Vinyl Acetate) Foam

A type of foam known for its flexibility, cushioning, and impact resistance. EVA foam is commonly used in sports equipment, footwear, and packaging. Used as the printable top layer of our PrintGuard foam.

Ester Foam

Ester, or Charcoal Ester, Foam is a soft, open-cell foam. Ester is sometimes preferred by customers with glass objects due to its shock absorbing properties.

Go to Foam Types to learn more.

Finger Notch

A finger notch is a cut or indentation in medium to dense foam designed to provide easy access, allowing items to be lifted out quickly and conveniently without damaging the foam. A finger notch is typically a 1” diameter circle.

Watch our Finger Notch Tutorial video to learn more.

Hand Notch

A finger notch is a cut or indentation in dense foam designed to provide easy access, allowing items to be lifted out quickly and conveniently without damaging the foam. A hand notch is typically a 3” x 1” rectangle with left and right finger notches.

Hole

An area of foam that cuts all the way through or exposes the case sides / wheels / handles. Typically we advise against holes in the foam. Sometimes, holes are fine if the cavity is for large cables or other items that need accommodation but not protection.

Impact Absorbency

The foam’s ability to absorb and dissipate energy from impacts or shocks, protecting the items it encloses from damage.

Lid Foam

Foam placed in the top portion of a protective case, providing additional cushioning and securing items when the case is closed.

Lid Filler Pad

A foam pad (or pads) added to the lid of a case to fill it to level for an accompanying insert. This is usually associated with cases employing a recessed center handle located on the case lid. The height of the LID FILLER PAD is usually NOT included in a case's LID DEPTH dimension.

PE (Polyethylene) Foam

A type of foam known for its durability and moisture resistance. It is commonly used in packaging and insulation. Our standard MyCaseBuilder foam is TopGuard PE.

PU (Polyurethane) Foam

A versatile foam material used in various applications including furniture, mattresses, and automotive interiors. It offers a range of densities and firmness levels. Our PU foam offering is Charcoal Ester.

PrintGuard Foam

PrintGuard is our Print-enabled Specialty Foam. It is the perfect surface to print on and also to protect and display your valuable items. It is made from a high density 1/4" EVA topper laminated to standard density Black Polyethylene foam. If you use PrintBuilder, PrintGuard Foam will automatically be applied to your project.

Go to Foam Types to learn more.

ProCell Foam

ProCell Foam is similar in density to TopGuard (PE), but has smaller cells which give it a smooth, suede-like finish and feel. ProCell is not suitable for industrial use as foam surface may pit or scar from rough handling. It is best in applications where a professional look is required, such as for presentations.

Go to Foam Types to learn more.

Recessed

When finished foam is shallower than the rim of the case base or lid.

Revealed

When finished foam protrudes past the rim of the case base or lid.

TopGuard (PE) Foam

TopGuard PE Foam consists of a ¼” high-density polyethylene topper heat laminated to a standard 1.7# polyethylene base foam. TopGuard is known for greater durability and stronger cavities. In addition to Black, the top surface TopGuard layer is also available in Red, Blue, and Yellow at no additional cost.

Go to Foam Types to learn more.

Tray

Our removable trays, or foam layers, can be created using TrayBuilder. The MyCaseBuilder app takes into consideration an added plastic, renforcing sheet and nylon riveted handles when creating trays using TrayBuilder so you can easily lift the tray out to access the gear beneath.

- If you prefer to add hand notches, the riveted handles are not required.

- If your items are not very heavy, you may choose not to have the plastic sheet or nylon riveted handles and only use the hand notches to remove your trays from the case.

- Watch our How to Create Lift Out Trays video to learn more.