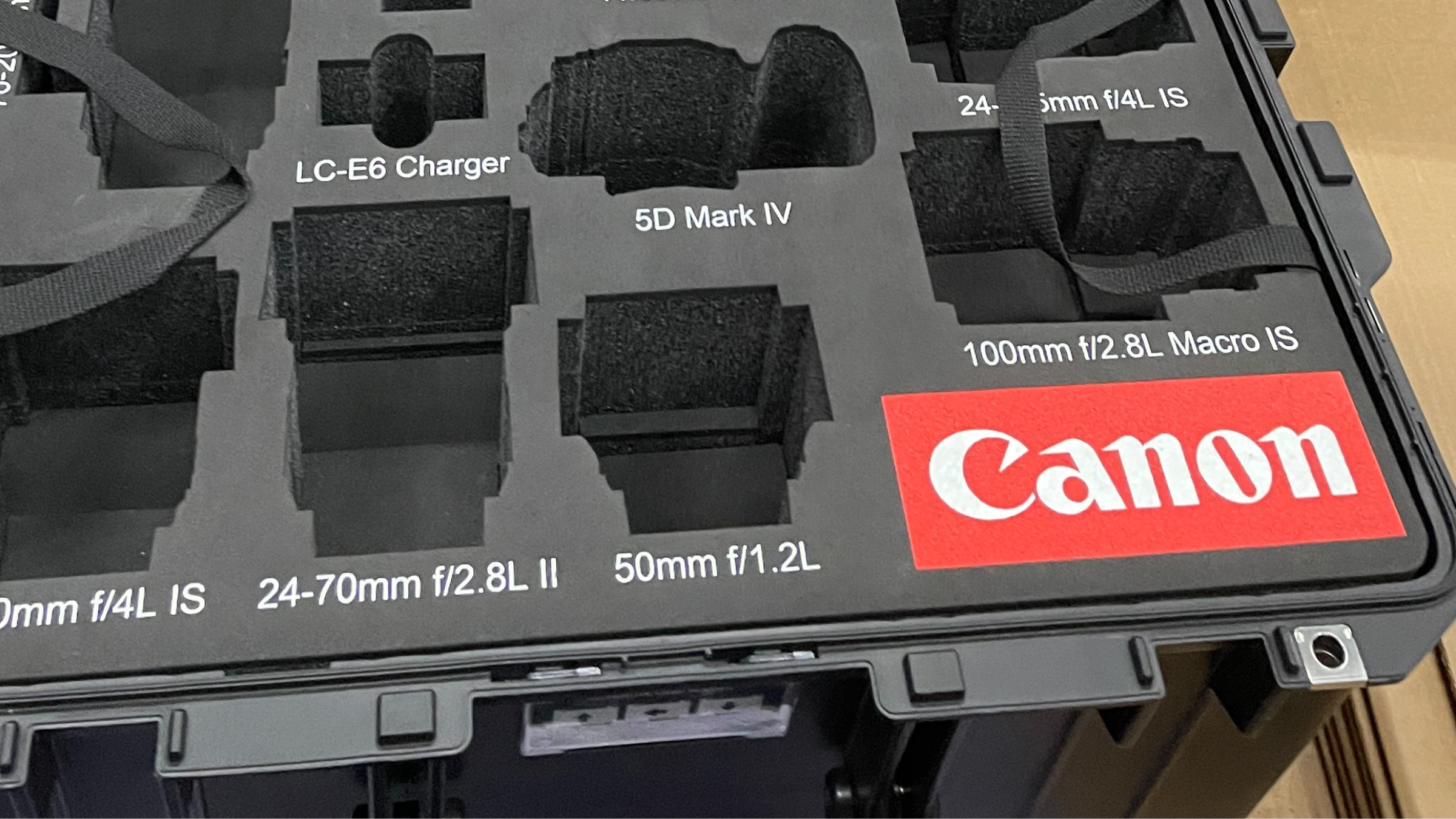

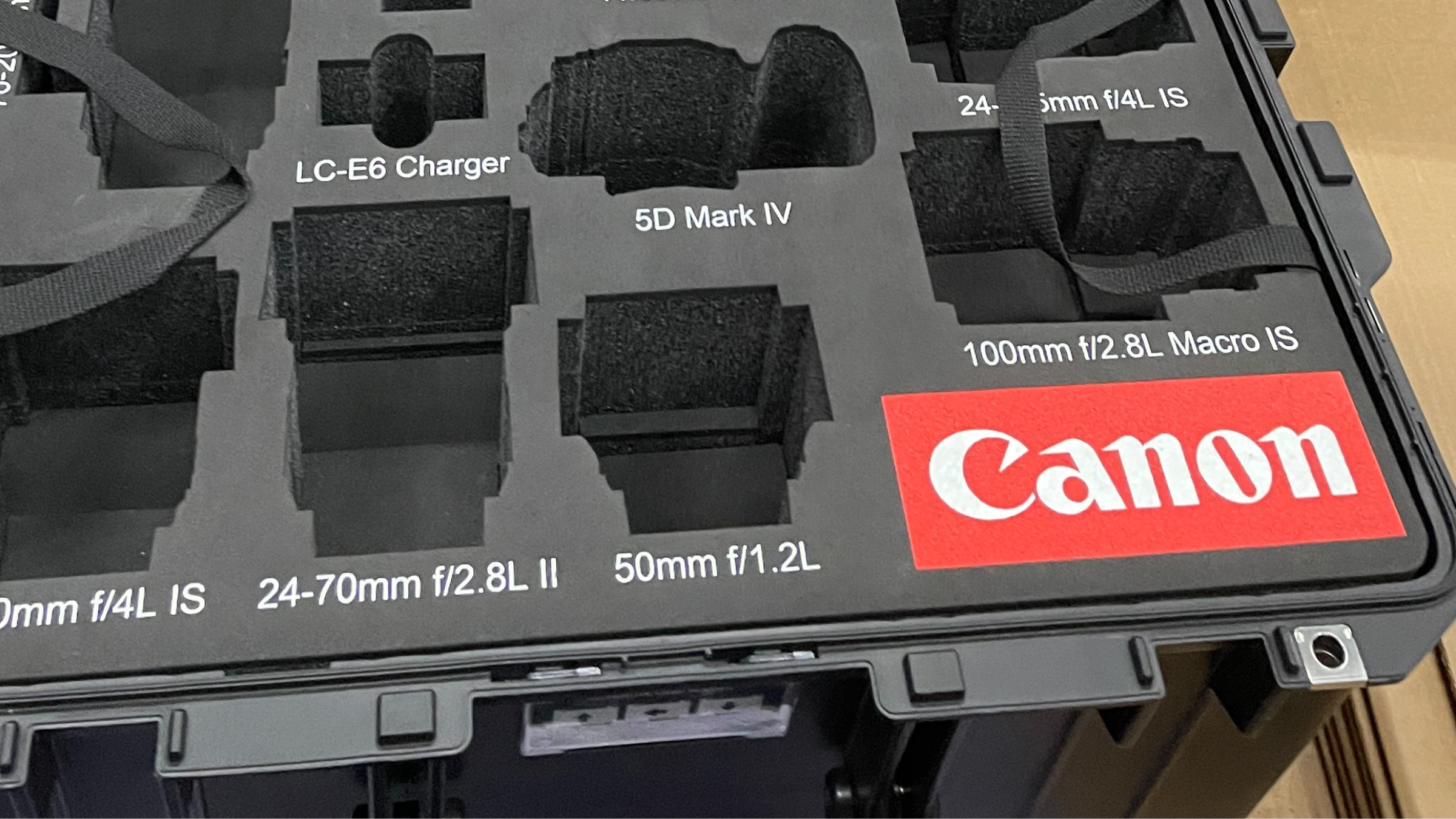

We use waterjet cutting to achieve precision details in foam, allowing us to create intricate shapes and designs tailored to your specifications.

This method is the main process we use for orders due to its precision and speed.

The process begins with a high-pressure pump that generates water at pressures typically ranging from 30,000 to 90,000 psi (pounds per square inch).

The high-pressure water is expelled through a small nozzle, creating a focused jet that is directed onto the material following a pre-programmed path that cuts out your shapes.